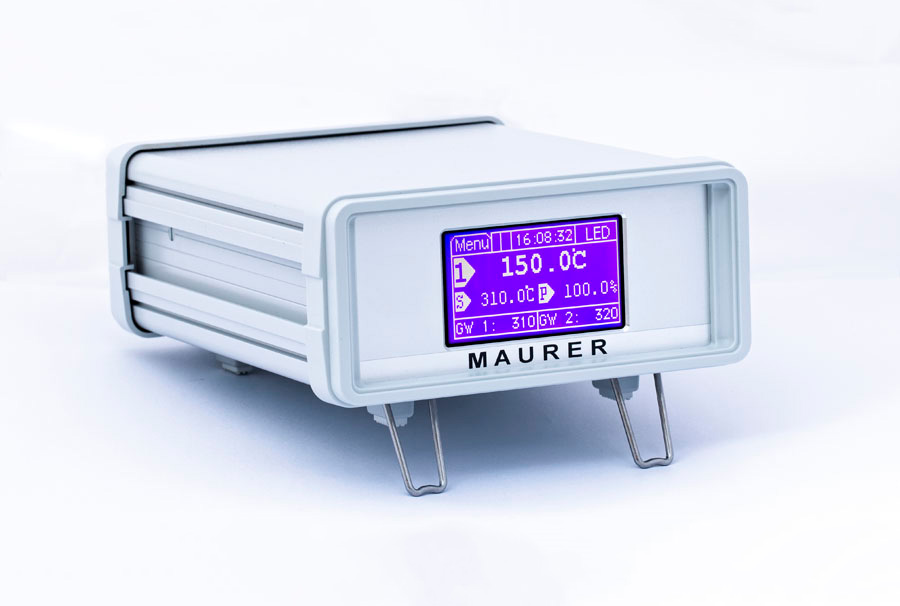

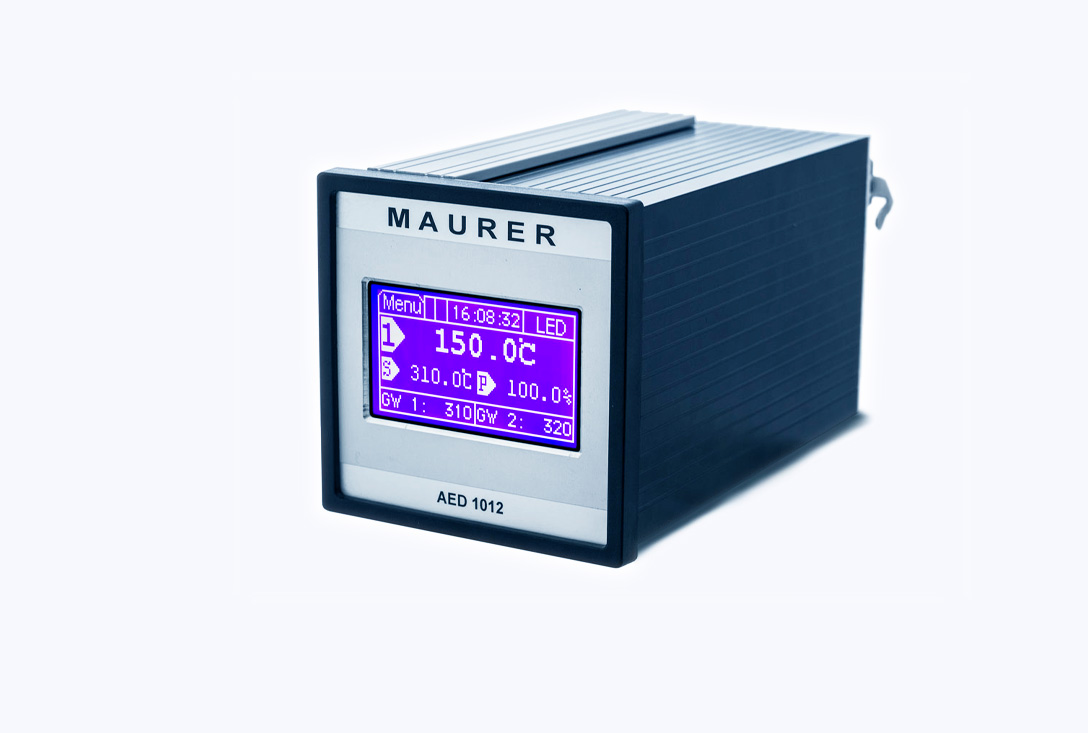

Complement your MAURER pyrometer with an electronic process unit and benefit from numerous functions. With this device you have all relevant data immediately in view. Adjusting the settings can be easily done thanks to the intuitive handling of the menu navigation. In addition, it enables you to record measured data and set the parameters for your pyrometer effortlessly and without a computer. For further control purposes, a large amount of data and signals can be tapped or fed from an external source via the terminal block on the rear side. Depending on the model, additional features are available for you. Please see the table below:

Electronic process units

Description

Features and characteristics of all models

AED 1012, AED 1012-C and AED 1012-PC:

-

- Display unit: gives an overview of all important information

- Overall parameter setting of pyrometer without computer possible

- 2 seperately adjustable switch outputs with optorelais

- Works as voltage supply for the pyrometer

- Digital pyrometer interface RS232 or RS485

- Authorization management with optional PIN protection against unauthorized access

- Automatic determination of emissivity and transmission

- Data logging to USB flash drive with real time clock

- Ultra fast sampling rate of 50 µsec

- Multilingual Touchpanel

- 6-digit temperature display °C / °F

Additional features and characteristics of the AED 1012-C

-

- PID Controller with set-point value setting (manually – external)

- Autotuning feature for automatic determination of PI-parameters

Additional features and characteristics of the AED 1012-PC

-

- PID Controller: define up to 500 programs with 1023 program steps in total

- Autotuning feature for automatic determination of PI-parameters

- 2 additional separately adjustable switch outputs with optorelais (4 in total)

Technical Data

stp-Files

Configuration & Assemblies

| Configuration Options | Equipment |

|---|---|

| Computer interface: ProfiBUS, ProfiNET, Ethernet, EtherCAT | Connection cables |

|

In DIN-housing according to DIN 43700 for panel

|

Mounting brackets for panel installation |

| Connection of second pyrometer via RS232 interface | Table top stand |

| Additional current output 0 (4) – 20 mA | Protection casing IP65 |

| Connection of up to 6 pyrometers via RS485 interface | Connection bar for up to 6 pyrometers (AED-6K) |

| Two additional switching outputs |